Galvanizing is a method that has been extensively used to shield different metals from corrosion for a long time. In this complete guide, we’ll dive into the intricate details of galvanizing and explore its background, types, processes, benefits, drawbacks and uses, and more. No matter if you’re an experienced engineer, DIY enthusiast or simply interested in the subject of the metallurgy industry, this article is intended to become the go-to source for all you need to learn about galvanizing.

What is Galvanizing?

Galvanizing is the process of applying a zinc coating on iron or steel to stop corrosion. The process involves soaking the metal in molten zinc making a bond, which creates a protective layer on the surface. The coating acts as a protective barrier keeping corrosive substances out of the metal beneath.

History of Galvanizing

The history of galvanizing could be traced back to the beginning of the 19th century, when Luigi Galvani, an Italian scientist discovered the consequences of galvanic corrosion. It wasn’t until the year 1830 that the current hot-dip galvanizing method was created in the 1830s by Sorel who was based in France. Since then, galvanizing’s technology has advanced by utilizing various techniques and methods being developed to meet different requirements.

Types of Galvanizing

Hot-Dip Galvanizing

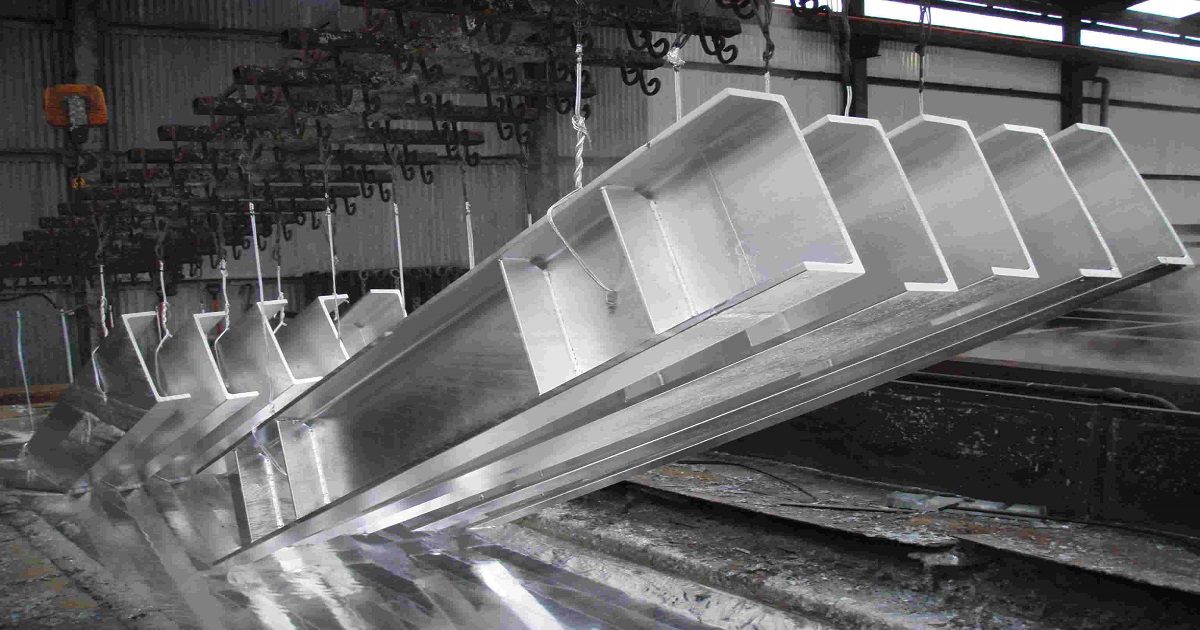

Hot-dip galvanizing is by far the most popular method. It involves the soaking of metal in the molten zinc bath. This process gives a thick and durable coating that makes it suitable for a broad variety of applications including automotive, construction and other industries.

Electro-Galvanizing

Electro-galvanizing is the process by which zinc is applied to the metal using the electrolytic procedure. This creates a thinner coating than galvanizing by hot dip, making it suitable for less delicate objects.

Sherardizing

Sherardizing is a process that involves heating zinc powder and absorbed into the surface of the metal, creating an impervious, uniform layer. This technique is typically employed for smaller parts.

Mechanical Galvanizing

Mechanical galvanizing is the process of tumbling metal components in a mix consisting of zinc powder and sand along with glass beads. The result is a coating that is created by mechanical action, and is an alternative to conventional galvanizing techniques.

The Galvanizing Process

The process of galvanizing involves a number of stages:

- Surface preparation: Metals are cleaned to get rid of any scale, rust, or other impurities.

- The process of fluxing: This metal has been coated with the flux solution to get rid of oxides and stop further oxidation prior galvanizing.

- Galvanizing: It is submerged in a bath of melting zinc at temperatures that are generally at 450°C (850degF).

- Quenching: Metal that has been galvanized is rapidly cooled in order to form that zinc layer.

- Inspect: The coated metal is inspected thoroughly to ensure that the high-quality and the thickness of the coat meets the requirements for.

Advantages of Galvanizing

Galvanizing can provide many advantages that include:

- Anti-corrosion: Zinc coating protects against corrosion in a superior way which extends the lifespan that the material has.

- Low maintenance: Surfaces galvanized require little maintenance, which lowers the total cost of the ownership.

- Multi-purpose: Galvanized metal can be utilized in a variety of settings from industrial to urban environments.

- Cost-effective: The initial cost of galvanizing might be higher, however the long-term benefits usually surpass the investment.

Disadvantages of Galvanizing

Although galvanizing can have many benefits however, it does have some negatives, like:

- Cosmetics: A shiny look of galvanized metal might not be suitable for some decorative or architectural purposes.

- Start Cost: Cost of initial galvanizing is higher than other methods of corrosion protection.

Galvanizing Applications

Galvanizing is extensively used in a variety of industries, such as:

- Construction: Structural steel columns, and beams.

- Automotive: Chassis, car parts and body parts.

- Services: Transmission towers, light poles, fencing.

- Marine: Offshore platforms and shipbuilding.

Galvanizing and Corrosion Protection

The main reason for galvanizing is to shield metal from corrosion. The zinc coating serves as an anode sacrificial, that is corroding instead of the metal underneath. This makes galvanized objects ideal for use in outdoor environments and areas that have corrosive elements.

Galvanizing Standards

A variety of standards regulate the process of galvanizing, which ensures high-quality and consistent results. The most common standards are ASTM A123 for hot dip galvanizing as well as ASTM A153, which governs zinc coatings on steel and iron.

FAQs

What kinds of materials are suitable for galvanizing?

Galvanizing is usually applied to iron and steel however it can also be applied on other metals, like aluminum.

How long will the galvanized coatings last?

The lifespan of galvanized coatings is dependent on a variety of factors, such as the conditions and the thickness of the coating. In general, it can last for several decades.

Does galvanized steel resist rust?

Yes galvanized steel is extremely resistant to rust because of the zinc coating, which protects it.

Can galvanizing be accomplished at home?

While galvanizing on a small scale is possible however, it is advised to delegate the work to experts due to safety issues and the requirement for special equipment.

What are the environmental consequences of galvanizing?

Although the process itself isn’t completely sustainable, the durability of galvanized products decreases the requirement for regular replacements, which contributes to sustainability.

Conclusion

In conclusion, galvanizing can be an efficient and flexible method of protecting metals against corrosion. Knowing the different types of galvanizing, their process involved, and the applications is essential for making educated choices in manufacturing, construction and other sectors. With its long tradition and continuous technological advancements galvanizing has remained a vital element in the field of metallurgy, guaranteeing the long-term durability and endurance of many products in various industries. It doesn’t matter if you’re an expert working in this field, or a person looking for information about the subject, this guide will give you everything you must be aware of about galvanizing.

Galvanizing stands as a robust solution for protecting metals from corrosion, offering durability, cost-effectiveness, and a wide range of applications. Whether in construction, automotive manufacturing, or utility infrastructure, the benefits of galvanizing make it a cornerstone in the world of metallurgy. As industries continue to evolve, so too will the techniques and applications of galvanizing, ensuring that it remains a vital process in preserving the integrity of metal structures for generations to come.